Grades of Stainless Steel & What They Mean for Your Foodservice Operation

Stainless steel is one of the most commonly used metal alloys. You can find it in industries from automotive to aviation to foodservice because of its excellent versatile properties. However, not all stainless steel is created equal. There are different grades of stainless steel, some of which are food-safe and some that are not. We’re often asked by restaurant operators which grade of stainless steel is the best for their operation.

We’re going to tackle this question for you by breaking down the different qualities of the two most commonly used grades of stainless steel in foodservice: 18/8 and 18/0.

Grade 18/8

This food-safe grade is the most popular type of stainless steel used in restaurants and commercial kitchens. Its versatility has earned it spots in both the front- and back-of-house for tabletop solutions, hollowware (pitchers, urns, gravy boats, etc.), and cookware pieces. Such broad applications really speak to this type of stainless steel’s adaptability.

Grade 18/8 steel is made of 18% chromium and 8% nickel, which is added to about 0.8% carbon and roughly 50% iron. The term 18/8 comes from listing the chromium amount as the first number and the nickel amount as the second. This is generally how you can tell the amount of chromium and nickel present in different types of stainless steel.

The chromium plays an important role in this alloy’s composition. It naturally bonds with oxygen, a chemical change, to create a layer that’s difficult for oxygen by itself to penetrate. Rust forms when oxygen and water combine with carbon. The layer created by the addition of chromium keeps oxygen out, removing one of the three elements necessary for rust to form. This makes grade 18/8 stainless steel anticorrosive.

Nickel generally contributes to the overall durability of this grade of stainless steel. The more nickel that’s present in stainless steel, the sturdier the steel will be. For example, 18/8 is sturdier than 18/0, which we’ll cover in the next section. Nickel is also what creates the luster that stainless steel is known for.

Grade 18/0

Comprised of 18% chromium and 0% nickel, 18/0 stainless steel is commonly used for mid-grade flatware and smaller capacity hollowware items like teapots. It’s typically less expensive than grade 18/8, which is one of the reasons it’s a popular choice for silverware, a high turnover item that often gets tossed out accidentally during the bussing process.

Because this grade doesn’t have any nickel, it won’t have the same luster as 18/8 stainless steel. The lack of nickel also means that 18/0 stainless steel doesn’t have the same anticorrosive properties as 18/8. But you’ll probably go through your 18/0 items fairly quickly, so you likely won’t need to worry about corrosion.

Similarities of Grades 18/8 and 18/0 Stainless Steel

Now that you know how these grades differ, let’s dive into what they can both do for your restaurant or commercial kitchen.

Durability

Durability is probably one of the most highly regarded properties of food-safe stainless steel, and one of the reasons it’s so widely used in foodservice. Whether it’s being used in the dining area or kitchen, grades 18/8 and 18/0 stainless steel can take a lot of rough handling. Grade 18/8 doesn’t crack, chip, pit, warp, or rust as easily as 18/0 can, but they can both withstand bustling kitchens and repeated tabletop use while still maintaining a great look.

Reaction to Food’s Natural Acids and Bases

Almost all foods are naturally acidic or basic (alkaline). There are some metals, like unseasoned cast iron, that do not stand up well to these properties and can corrode over time if not cared for properly. Both grades of stainless steel discussed here do not have that problem.

With food-safe stainless, there is zero reaction to either of these chemical compounds, which is a win-win. Operators win because acids and bases won’t corrode their stainless cookware, which leads to a long service life. Guests and operators alike don’t have to worry about the taste, appearance, or smell of their food being affected by the metal it’s cooked in or served on.

Sanitation

One of the most important qualities of any foodservice operation is creating and maintaining sanitary conditions. Both grades 18/8 and 18/0 stainless steel perform exceptionally well in this area for a few reasons.

Remember the protective layer created by chromium bonding to oxygen that we mentioned earlier? Not only does it keep oxygen out of the metal, but it also creates a non-porous surface. This means that food particles can’t seep into the metal to create unsanitary conditions. Food that comes into contact with these grades of stainless stays on the surface, which makes it very easy to clean.

Additionally, stainless steel’s ability to be manufactured with very smooth surfaces is another sanitary advantage. Rough surfaces can hide food, making them more difficult to clean. When it comes to food-grade stainless, however, there’s nowhere for food to hide.

Sturdiness

Food-safe stainless steel is not as heavy as cast iron, nor as light as aluminum. It fits nicely between those two metals in terms of weight, which can be an advantage.

It’s not so heavy that it’s cumbersome to carry on a tray or move around a kitchen like cast iron can be. But it also can’t be knocked over as easily as lightweight aluminum. For tabletop pieces, grades 18/8 and 18/0 stainless steel can be trusted as a sturdy and great-looking addition that your guests will love and your staff can easily move around your restaurant or commercial kitchen.

Customization

Speaking of how great stainless steel can look, another area where operators find value is in its ability to be customized and produced with different types of finishes.

Any restaurant owner knows how important branding is. It’s a crowded industry, and setting your operation apart from all the other ones out there seems like half the battle sometimes.

If you’re interested in using stainless steel on your tabletops, or for guest-facing pieces like tea and water pitchers, you can get custom branded art either laser etched or embossed for an extra cost. That can pay off in the long run because it’s an elegant way to reinforce your brand using products that are already highly visible to your guests.

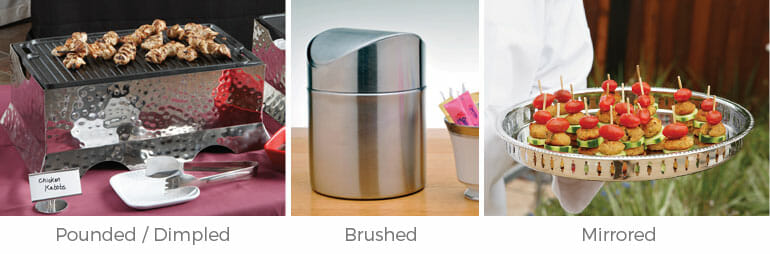

Depending on the tone you want to set, you can choose from a variety of finishes on your guest-facing stainless steel pieces. You could go with a pounded, or dimpled, finish for a playful look. Brushed stainless steel is a timeless and elegant look that also helps to cover up fingerprints and smudges. Or you could opt for a mirrored finish. It would show fingerprints and smudges more readily than the other finishes, but if you’d like to use these pieces in a decorative way where they won’t be handled often, then you don’t need to worry about it.

Here at G.E.T., we’re always looking out for you and constantly working toward creating helpful educational pieces so that you can get the very best out of your tableware and cookware with just a few clicks. This should help light the way for you to find the best food-safe stainless steel for your particular option. If you’re interested in reading more about other types of materials used in foodservice, we recommend reading “PC vs SAN Plastic Tumblers: What’s the Difference?“

{{cta(‘8d97949d-5da3-4d20-be7d-c81134328a61’)}}